Abstract

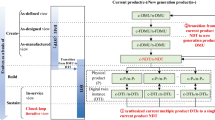

In recent years, green concepts have been integrated into the product iterative design in the manufacturing field to address global competition and sustainability issues. However, previous efforts for green material optimal selection disregarded the interaction and fusion among physical entities, virtual models, and users, resulting in distortions and inaccuracies among user, physical entity, and virtual model such as inconsistency among the expected value, predicted simulation value, and actual performance value of evaluation indices. Therefore, this study proposes a digital twin-driven green material optimal selection and evolution method for product iterative design. Firstly, a novel framework is proposed. Subsequently, an analysis is carried out from six perspectives: the digital twin model construction for green material optimal selection, evolution mechanism of the digital twin model, multi-objective prediction and optimization, algorithm design, decision-making, and product function verification. Finally, taking the material selection of a shared bicycle frame as an example, the proposed method was verified by the prediction and iterative optimization of the carbon emission index.

Similar content being viewed by others

References

Govindan K, Shankar KM, Kannan D (2016) Sustainable material selection for construction industry—a hybrid multi criteria decision making approach. Renew Sustain Energy Rev 55:1274–1288

Seyed AH, Saeed M, Mohsen AS (2014) Social life cycle assessment for material selection: a case study of building materials. Int J Life Cycle Assess 19:620–645

Fehim F, Kemal T (2012) Materials selection for lighter wagon design with a weighted property index method. Mater Des 37:470–477

Apple_Environmental_Progress_Report_2020. https://www.apple.com/euro/environment/pdf/a/generic/Apple_Environmental_Progress_Report_2020.pdf. Accessed 10 Feb 2022

Xiang F, Huang YY, Zhang Z et al (2019) A new mode of green manufacturing for product life cycle based on digital twin. Comput Integr Manuf Syst 25(6):1505–1514

Peças P, Ribeiro I, Silva A et al (2013) Comprehensive approach for informed life cycle-based materials selection. Mater Des 43:220–232

Venkata RR (2008) A decision making methodology for material selection using an improved compromise ranking method. Mater Des 29(10):1949–1954

Gong QS, Zhang H, Jiang ZG et al (2019) Nonempirical hybrid multi-attribute decision-making method for design for remanufacturing. Adv Manuf 7:423–437

Tao F, Zhang H, Qi QL et al (2021) Theory and application of digital twin model construction. Comput Integr Manuf Syst 27(1):1–15

Kosacka M, Kostrzewski M, Marczewska M et al (2021) How digital twin concept supports internal transport systems?—Literature review. Energies 14:4919. https://doi.org/10.3390/en14164919

van der Valk H, Haße H, Möller F et al (2020) A taxonomy of digital twins. In: The 26th Americas conference on information systems, 15–17 August, Salt Lake City

Tao F, Zhang CY, Zhang H et al (2022) Future gear exploration: digital twin gear. Comput Integr Manuf Syst 28(1):1–16

Liu SM, Lu YQ, Li J et al (2021) Multi-scale evolution mechanism and knowledge construction of a digital twin mimic model. Robot Comput Integr Manuf 71:102123. https://doi.org/10.1016/j.rcim.2021.102123

Li H, Tao F, Wang HQ et al (2019) Integrated development framework and key technology of complex product design and manufacturing based on digital twin. Comput Integr Manuf Syst 25(6):1320–1336

Zhuang CB, Liu JH, Xiong H et al (2017) The connotation, system structure and development trend of product digital twin. Comput Integr Manuf Syst 23(4):753–768

Yi Y, Yan YH, Liu XJ et al (2021) Digital twin-based smart assembly process design and application framework for complex products and its case study. J Manuf Syst 58:94–107

van Raymon D, Bedir T, Cagatay C (2022) Predictive maintenance using digital twins: a systematic literature review. Inf Softw Technol 151:107008. https://doi.org/10.1016/j.infsof.2022.107008

Peter O, Jing ZT, Thomas W (2022) Computational optimization for circular economy product design. J Clean Prod 362:132340. https://doi.org/10.1016/j.jclepro.2022.132340

Ji X, Gao Q, Wang H (2022) A bilevel-optimization approach to determine product specifications during the early phases of product development: increase customer value and reduce design risks. Expert Syst Appl 188:116012. https://doi.org/10.1016/j.eswa.2021.116012

Sandanayake M, Gunasekara C, Law D et al (2020) Sustainable criterion selection framework for green building materials—an optimization based study of fly-ash geopolymer concrete. Sustain Mater Technol 25:e00178. https://doi.org/10.1016/j.susmat.2020.e00178

Tian GD, Zhang HH, Feng YX et al (2018) Green decoration materials selection under interior environment characteristics: a grey-correlation based hybrid MCDM method. Renew Sustain Energy Rev 81(1):682–692

Zhang HH, Wu YY, Wang K et al (2020) Materials selection of 3D-printed continuous carbon fiber reinforced composites considering multiple criteria. Mater Des 196:109140. https://doi.org/10.1016/j.matdes.2020.109140

Zhou CC, Yin GF, Hu XB (2009) Multi-objective optimization of material selection for sustainable products: artificial neural networks and genetic algorithm approach. Mater Des 30(4):1209–1215

Tao F, Bi LN, Zuo Y et al (2016) A hybrid group leader algorithm for green material selection with energy consideration in product design. CIRP Ann 65(1):9–12

Zhang XJ, Chen KZ, Feng XA (2008) Material selection using an improved genetic algorithm for material design of components made of a multiphase material. Mater Des 29(5):972–981

Xiang F, Zhang Z, Zuo Y et al (2019) Digital twin driven green material optimal-selection towards sustainable manufacturing. Proc CIRP 81:1290–1294

Zhang H, Liu Q, Chen X et al (2017) A digital twin-based approach for designing and multi-objective optimization of hollow glass production line. IEEE Access 5:26901–26911

Tao F, Zhang M (2017) Digital twin shop-floor: a new shop-floor paradigm towards smart manufacturing. IEEE Access 5:20418–20427

Tao F, Qi QL, Liu A et al (2018) Data-driven smart manufacturing. J Manuf Syst 48:157–169

Tao F, Cheng Y, Chen JF et al (2017) Theories and technologies for cyber- physical fusion in digital twin shop-floor. Comput Integr Manuf Syst 23(8):1603–1611

Tao F, Zhang M, Liu YS et al (2018) Digital twin driven prognostics and health management for complex equipment. CIRP Ann 67(1):169–172

Qi QL, Tao F (2018) Digital twin and big data towards smart manufacturing and Industry 4.0: 360 degree comparison. IEEE Access 6:3585–3593

Guo JP, Zhao N, Sun L et al (2018) Modular based flexible digital twin for factory design. J Ambient Intell Humaniz Comput 10:1189–1200

He B, Bai KJ (2020) Digital twin-based sustainable intelligent manufacturing: a review. Adv Manuf 9:1–21

Lennart YL (2007) Materials selection and design for development of sustainable products. Mater Des 28(2):466–479

Lu JF, Xia LY, Bai O et al (2021) Study on the whole life cycle of product digital twin under intelligent manufacturing. Process Autom Instrum 42(3):1–7

Li Y, Liu Q (2015) Service-oriented research on multi-pass milling parameters optimization for green and high efficiency. J Mech Eng 51(11):89–98

Deng ZH, Fu YH, Wan LL et al (2017) Multi objective optimization of milling process parameters for green high-performance manufacturing. China Mech Eng 28(19):2365–2372

Wang RH, Jie PF, Wang DL et al (2021) Optimization of insulation thickness of double buried district heating pipes using the Eco-indicator method. J Build Eng 41:102393. https://doi.org/10.1016/j.jobe.2021.102393

Wang KS (2013) Towards zero-defect manufacturing (ZDM)—a data mining approach. Adv Manuf 1:62–74

Tao F, Zhang CY, Qi QL et al (2022) The maturity model of digital twin. Comput Integr Manuf Syst 28(5):1267–1281

Chen DD, Lin YC, Chen XM (2019) A strategy to control microstructures of a Ni-based superalloy during hot forging based on particle swarm optimization algorithm. Adv Manuf 7:238–247

Agathocle AK, Nikolaos AF (2016) Balancing multiple criteria in formulation of weighted, single-objective genetic algorithm optimization for CNC machining problems. Adv Manuf 4:178–188

Rityuj SP, Raj KS, Srinivasu GS (2020) Novel design and composition optimization of self-lubricating functionally graded cemented tungsten carbide cutting tool material for dry machining. Adv Manuf 9:34–46

MatWeb. https://matweb.com/. Accessed 7 Apr 2022

MetalChina. https://www.metalchina.com/. Accessed 7 Apr 2022

Liu JF, Wen XJ, Zhou HG et al (2022) Digital twin-enabled machining process modeling. Adv Eng Inform 54:1–13

Wang L, Luo ZD, Tang HT (2023) A novel model for dynamic manufacturing service collaboration on industrial internet. IEEE Trans Ind Inform. https://doi.org/10.1109/TII.2023.3252408

Acknowledgment

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51975431 and 52005025), and the Fundamental Research Funds for the Central Universities (Grant No. 51705379) in China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g., a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiang, F., Zhou, YD., Zhang, Z. et al. Digital twin-driven green material optimal selection and evolution in product iterative design. Adv. Manuf. 11, 647–662 (2023). https://doi.org/10.1007/s40436-023-00450-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-023-00450-4