Abstract

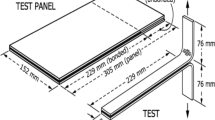

The effect of molecular weight and testing rate on peel and shear strength of epoxidized natural rubber (ENR-50)-based adhesive was investigated using petro resin as the tackifier. Toluene and polyethylene terephthalate were used as the solvent and substrate respectively. Peel and shear strength were determined by a Llyod Adhesion Tester operating at different rates of testing. Result shows that peel strength and shear strength increases up to an optimum molecular weight of 4.2 × 104 g/mol of ENR-50. This observation is attributed to the combined effects of wettability and mechanical strength of rubber for peel strength. For shear strength, it is ascribed to the optimum cohesive and adhesive strength. Both peel strength and shear strength increases with increasing rate of testing, an observation which is associated to the viscoeslastic response of the adhesive. Thermal study, SEM and FTIR study confirms the miscibility of tackifier with ENR-50.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Abbreviations

- ASTM:

-

American Society for Testing and Materials

- AO-80:

-

3,9-bis[1,1-dimethyl-2{β-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionyloxy}ethyl]-2,4,8,10-tetraoxaspiro[5,5]-undecane

- ENR:

-

Epoxidized natural rubber

- NR:

-

Natural rubber

- PET:

-

Polyethylene terephthalate

- PVP:

-

Poly (vinylpyrrolidone)

- PSA:

-

Pressure-sensitive adhesive

References

Olabisi O, Robeson LM, Shaw MT (1979) Polymer–polymer miscibility. Academic Press, New York ch. 4

Paul DR, Newman S (1978) Polymer blends, vol 2. Academic Press, New York ch. 12

Mekhilef N, Favis BD, Carreau PJ (1997) Morphological stability, interfacial tension and dual-phase continuity in polystyrene-polyethylene blends. J Polym Sci Pol Phys 35:293–308

Ismail H, Tan S, Poh BT (2001) Curing, mechanical properties of nitrile, natural rubber blends. J Elastom Plast 33:251–262

Satas D (ed) (1982) Handbook of pressure-sensitive adhesive technology, 191, 54, Van Nostrand Reinhold, New York

Margaritis AG, Kalfoglou NK (1987) Miscibility of chlorinated polymers with epoxidized poly(hydrocarbons). 1. Epoxidized natural rubber/poly(vinyl chloride) blends. Polymer 28:497–502

PSTC (2008) Single coated pressure sensitive tape. Pressure Sensitive Tape Council, Northbrook

Benedek I (2004) Pressure-sensitive adhesives and applications. Marcel Dekker, New York

Dahlquist CA (1989) In: Satas D (ed) Pressure sensitive adhesive technology, 2nd ed, chap 20. Van Nostrand Reinhold: New York, p 97

Bendek I (1999) Development and manufacture of pressure-sensitive products. Marcel Dekker, New York

Webster. I (1997) Recent developments in pressure-sensitive adhesives for medical applications. Int J Adhes Adhes 17:69–73

Lee LH (ed) (1991) Adhesive bonding. Plenum Press, New York, p 19

Skeist I (ed) (1990) Handbook of adhesives, 3rd edn. Van Nostrand Reinhold, New York

de Gennes PG (1995) Spontaneous adhesion between rubbers and bare solids. Acad Sci Paris 320:193–197

Satas I (1989) Peel. In: Satas I (ed) Handbook of pressure sensitive adhesive technology. Van Nostrand Reinhold, New York, p 61

Choi GY, Zurawsky W, Ulman A (1999) Molecular weight effects in adhesion. Langmuir 15:8447–8450

Pal K, Rajasekar R, Kang DJ, Zhang ZX, Pal SK, Das CK, Kim JK (2010) Effect of fillers on natural rubber/high styrene rubber blends with nano silica: morphology and wear. Mater Des 31:677–686

Li C, Cao D, Guo W, Wu C (2008) The investigation of miscibility in blends of ENR/AO-80 by DMA and FT-IR. J Macromol Sci Phys 47:87–97

Taghizadeh SM, Mirzadeh H, Barikani M, Yousefi M (2009) Miscibility and tack of blends of poly (vinylpyrrolidone)/acrylic pressure-sensitive adhesive. Int J Adhes Adhes 29:302

Allen KW (1987) A review of contemporary views of theories of adhesion. J Adhes 21:261–277

Poh BT, Yong AT (2010) Effect of molecular weight of epoxidized-natural rubber on viscosity, tack of pressure-sensitive adhesives. J Appl Polym Sci 115:1120–1124

Poh BT, Yong AT (2009) Dependence of peel adhesion on molecular weight of epoxidized natural rubber. J Adhes 85:435–446

Poh BT, Yong AT (2009) Effect of molecular weight of rubber on tack, peel strength of SMR L-based pressure-sensitive adhesives using gum rosin, petroresin as tackifiers. J Macromol Sci Chem 46:97–103

Khan I, Poh BT (2010) The effect of silica on the peel adhesion of epoxidized natural rubber-based adhesive containing coumarone-indene resin. J Polym Plast Technol Eng 49:1356–1360

Khan I, Poh BT (2011) Effect of molecular weight, testing rate on adhesion property of pressure-sensitive adhesives prepared from epoxidized natural rubber. Mater Des 32:2513–2519

Khan I, Poh BT (2011) Effect of molecular weight, testing rate on peel, shear strength of epoxidized natural rubber (ENR-50)-based adhesives. J Appl Polym Sci 120:2641–2647

Issam AM, Poh B, Abdul Khalil H, Lee W (2009) Adhesion properties of adhesive prepared from waste polystyrene. J Polym Environ 17:165–169

Poh BT, Firdaus SZ (2010) Effect of hybrid tackifiers on adhesion properties of epoxidized natural rubber-based pressure-sensitive adhesives. J Polym Environ 18:335–338

Khan I, Poh BT (2011) Natural rubber-based pressure-sensitive adhesives: a review. J Polym Environ 19:793–811

Poh BT, Chow SK (2007) Effect of zinc oxide on the viscosity, tack, and peel strength of ENR 25-based pressure-sensitive adhesives. J Appl Polym Sci 106:333–337

Poh BT, Lee PG, Chuah CS (2008) Adhesion property of epoxidized natural rubber (ENR)-based adhesives containing calcium carbonate. Expess Polym Lett 2:398–403

Khan I, Poh BT (2010) Effect of silica on viscosity, tack, and shear strength of epoxidized natural rubber-based pressure-sensitive adhesives in the presence of coumarone-indene resin. J Appl Polym Sci 118:3439–3444

Poh BT, Gan CF (2010) Viscosity and peel strength of magnesium oxide-filled adhesive prepared from epoxidized natural rubber ENR 25. J Polym Plast Technol Eng 49:191–194

Poh BT, Chew CE (2009) Effect of kaolin on adhesion property of epoxidized natural rubber-based pressure-sensitive adhesive using gum rosin as the tackifier. J Elastom Plast 41:447–456

Khan I, Poh BT, Badriah CM (2011) Effect of sodium sulfate on the viscosity, tack, and adhesion properties of SMR 10-based pressure-sensitive adhesive. J Elastom Plast 43:85–95

Poh BT, Tan BK (1991) Mooney scorch time of epoxidized natural rubber. J Appl Polym Sci 42:1407–1416

Billmeyer FW Jr (ed) (1984) Textbook of polymer science, 3rd edn. Wiley, New York, p 208

Bateman L (1963) The chemistry and physics of rubber-like substances. Maclaren Ed, London, p 149

Brandrup J, Immergut EH, Grulke EA, Abe A, Bloch DR, Daniel R (2005) Polymer handbook, 4th edn. Wiley, New York

ASTM D907-03, Terminology of Adhesives (2004) Annual book of ASTM standards, vol 15.06. American Society for Testing and Materials, Philadelphia

Somanathan N, Sanjay A, Arumugam V (2002) Compatibility studies on polystyrene, poly-n-butyl methacrylate. J Appl Polym Sci 83:2322–2330

Hayashi S, Kim H-J, Kajiyama M, Ono H, Mizumachi H, Zufu Z (2000) Miscibility and pressure-sensitive adhesive performances of acrylic copolymer and hydrogenated rosin systems. J Appl Polym Sci 71:651–663

Gordon M, Taylor JS (1952) Ideal copolymers, the second-order transitions of synthetic rubbers. I. Non-crystalline copolymers. J Appl Chem 2:493–500

Zerjal B, Jelcic Z, Malavasic T (1996) Miscibility in thermoplastic polyurethane elastomer/poly(styrene-co-acrylonitrile) blends. Eur Polym J 32:1351–1354

Song M, Hammiche A, Pollock HM, Hourston DJ, Reading M (1995) Modulated differential scanning calorimetry: 1. A study of the glass transition behavior of blends of poly(methyl methacrylate) and poly(styrene-co-acrylonitrile). Polymer 36:3313–3316

Fox TG (1956) Influence of diluent and of copolymer composition on the glass temperature of a polymer system. Bull Am Phys Soc 1:123

Noriman NZ, Ismail H, Rashid AA (2010) Characterization of styrene butadiene rubber/recycled acrylonitrile-butadiene rubber (SBR/NBRr) blends: the effects of epoxidized natural rubber (ENR-50) as a compatibilizer. Polym Test 29:200–208

Sasaki M, Fujita K, Adachi M, Fujii S, Nakamura Y, Urahama Y (2008) The effect of tackifier on phase structure, peel adhesion of a triblock copolymer pressure-sensitive adhesive. Int J Adhes Adhes 28:372–381

Acknowledgments

The authors acknowledge the research grant (FRGS) and post doctoral funding provided by Universiti Sains Malaysia that has resulted in this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, I., Poh, B.T. Material Properties and Influence of Molecular Weight and Testing Rate on Adhesion Properties of Epoxidized Natural Rubber-Based Adhesives. J Polym Environ 20, 132–141 (2012). https://doi.org/10.1007/s10924-011-0369-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-011-0369-2

Keywords

Profiles

- Imran Khan View author profile